Advantages of 88% Cotton 12% Nylon FR Fabric | Strong, Durable & Comfortable

In industrial protective clothing, flame retardant (FR) fabrics must not only resist flames but also provide strength, durability, and comfort. For fabrics with the same weight, 88% cotton 12% nylon FR fabric shows clear advantages over 100% cotton Flame Retardant fabric in durability and tear resistance, while maintaining cotton’s natural comfort.

Effect of Flame Retardant Treatment on Fabric Performance

100% cotton FR fabric can lose some fiber strength and tear resistance during flame retardant finishing. However, it still offers high comfort and breathability. By blending 12% nylon, the fabric maintains strength and durability while keeping the soft, breathable feel of cotton:

- Higher fiber strength: Nylon strengthens overall fabric strength

- Improved tear resistance: Reduces the risk of damage during work

- Enhanced durability: Handles frequent friction and heavy use

- Cotton comfort retained: Soft, breathable, and suitable for long wear

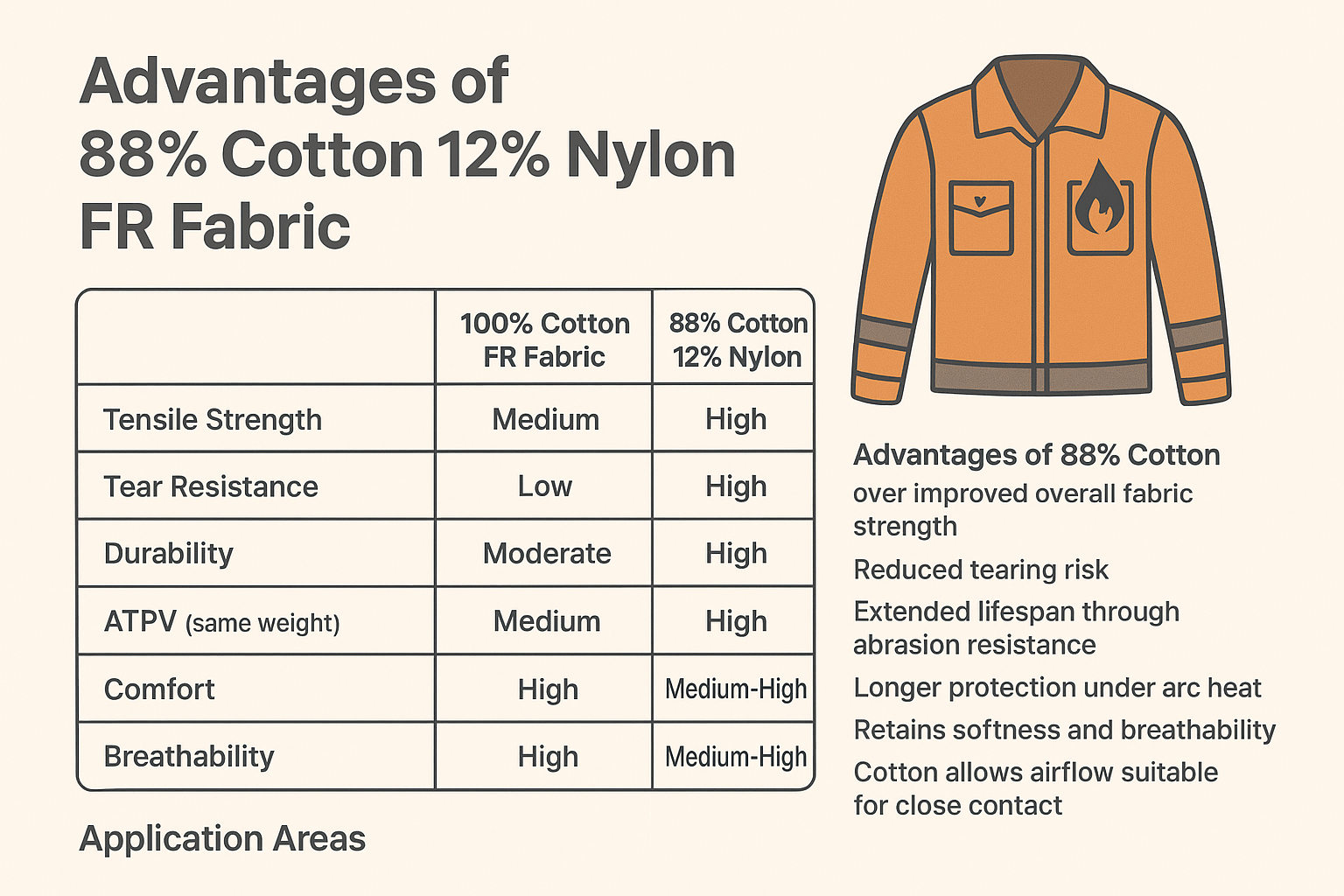

88% Cotton 12% Nylon Flame Retardant Fabric vs 100% Cotton Flame Retardant Fabric

| Feature | 100% Cotton FR Fabric | 88% Cotton 12% Nylon FR Fabric | Advantage |

|---|---|---|---|

| Tensile Strength | Medium | High | Nylon improves overall fabric strength |

| Tear Resistance | Low | High | Blend reduces tearing risk |

| Durability | Moderate | High | Nylon resists abrasion and extends lifespan |

| ATPV (same weight) | Medium | High | Provides longer protection under arc heat |

| Comfort | High | Medium-High | Cotton retains softness and breathability |

| Breathability | High | Medium-High | Cotton allows air flow, suitable for close contact |

Note: ATPV = Arc Thermal Performance Value. A higher value means longer protection time against electric arc or high heat.

Application Areas

- Welding, petrochemical, and high-temperature industrial work

- Arc flash protective clothing, industrial FR clothing, and fire safety uniforms

- Work environments that require durable FR fabric with high tear resistance and comfort

FAQ (Frequently Asked Questions)

Q1: Why choose 88% cotton 12% nylon FR fabric instead of 100% flame retardant cotton?

A1: The blended fabric retains higher strength and tear resistance after flame retardant treatment, while keeping cotton’s softness and breathability. It is suitable for high-intensity work.

Q2: Will flame retardant performance decrease due to the blend?

A2: No. 88% cotton 12% nylon flame retardant fabric meets international standards such as EN ISO 11611 and 11612.

Q3: Does comfort or breathability get affected?

A3: Since cotton still accounts for the majority, the fabric stays soft, breathable, and comfortable for close-contact wear.

Q4: Which industries is this fabric suitable for?

A4: Welding, petrochemical, electric power, manufacturing, and fire safety industries that need high-temperature protection with durability and comfort.

Q5: Are samples available for testing?

A5: Yes, small sample orders are available, allowing customers to verify fabric performance before bulk purchase.

Learn More

To learn more about 88% cotton 12% nylon FR fabric, its specifications, sample policy, and ordering details, please visit our product page.