Many buyers search for Proban Fabric when sourcing high-performance flame-retardant materials. In China and in the textile industry, many refer to this fabric as THPC Fabric. Industry professionals also use the term THPC Finishing Fabric.

This guide explains the relationship between Proban Fabric and THPC Fabric. Moreover, it shows why manufacturers use THPC finishing as the standard technology for producing durable flame-retardant cotton fabrics.

1. How is Proban fabric made?

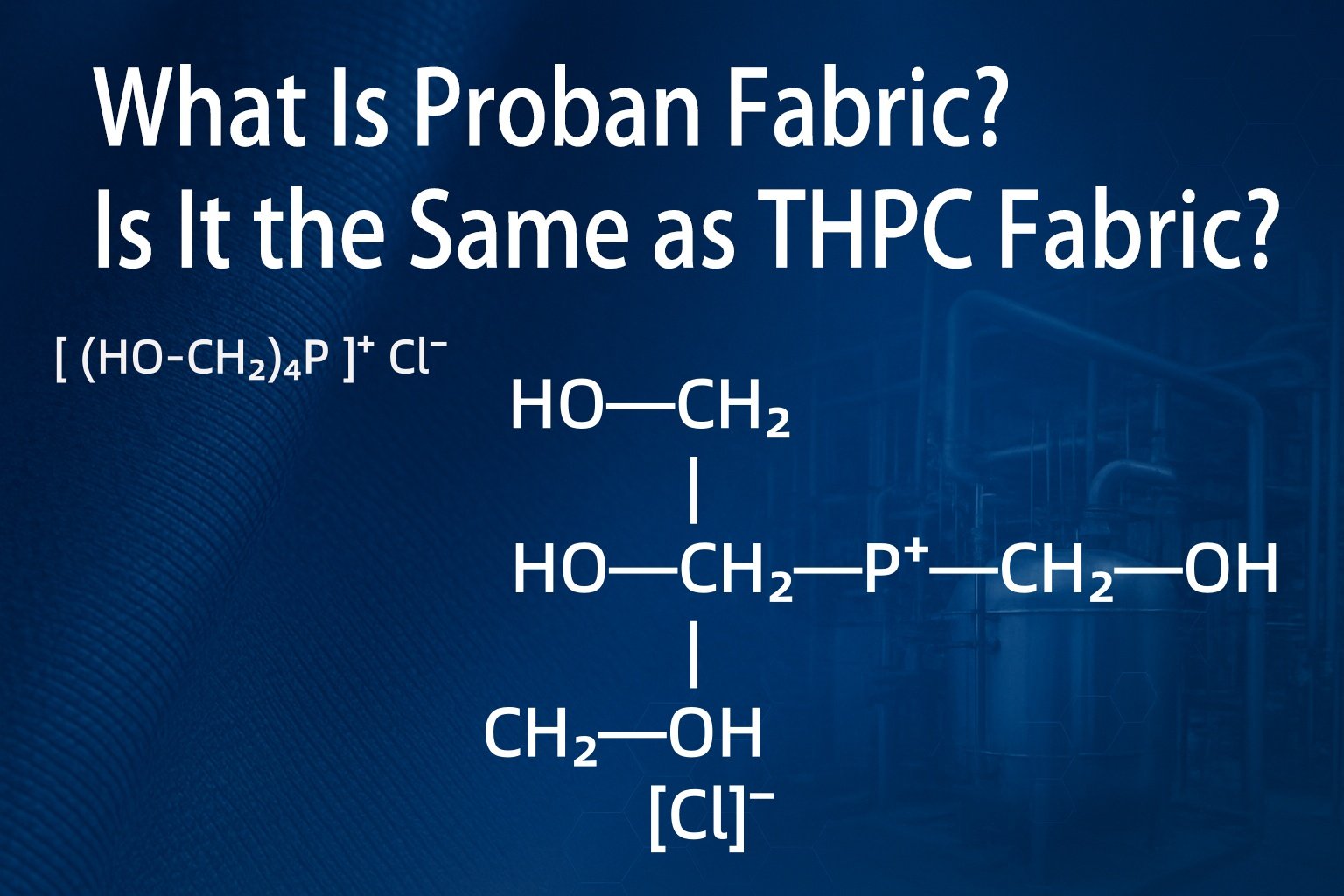

Proban Fabric is a durable flame-retardant cotton fabric made using the THPC (Tetrakis Hydroxymethyl Phosphonium Chloride) ammonia-curing process. This chemical treatment forms a permanent phosphorus–nitrogen polymer inside the fibers, providing long-lasting flame resistance.

Because of its performance, Proban Fabric is widely used in:

- Oil & Gas workwear

- Industrial uniforms

- Welding garments

- Electrical and utility PPE

Its durability, breathability, and protection make it one of the most trusted FR solutions on the market.

2. How THPC Finishing Works in Flame Retardant Fabric Production

The THPC finishing process is the core technology behind both Proban Fabric and THPC Fabric.

Step 1 – THPC Padding

Cotton fabric is padded in a THPC solution to ensure deep penetration of the flame-retardant agent.

Step 2 – Ammonia Curing

The fabric reacts with ammonia to form a cross-linked polymer inside the fibers. This step is essential to give THPC Fabric its permanent flame-retardant structure.

Step 3 – Oxidation and Neutralization

The polymer is stabilized to ensure long-term durability.

Step 4 – Washing & Drying

Residual chemicals are removed, making the fabric clean, stable, and safe for contact with skin. Residual chemicals are removed, making the fabric clean, stable, and safe for contact with skin. The flame-retardant structure forms inside the fibers. As a result, THPC Finishing Fabric provides exceptional washing durability, which is a key advantage for industrial workwear.

3. Why China Uses “THPC Fabric” Instead of “Proban Fabric”

Although Proban® is a globally recognized brand, it is not authorized for production in China. Chinese manufacturers, however, produce the same technology using THPC and the ammonia-curing process.

Thus, in China and many Asian markets, the professional terms are:

- THPC Fabric

- THPC finishing Fabric

- Ammonia-cured flame-retardant cotton

These refer to the same flame-retardant structure found in Proban®-type fabrics. For international buyers:

THPC Fabric is functionally equivalent to Proban Fabric — it delivers the same performance without the brand label.

For buyers seeking Proban-type performance at competitive pricing, THPC finishing Fabric is the standard choice.

4. Are Proban Fabric and THPC Fabric the Same?

Yes. Both refer to the same flame-retardant technology.

| Term | Meaning | Notes |

|---|---|---|

| Proban Fabric | Branded version of THPC FR fabric | Trademarked, not made in China |

| THPC Fabric | Technical name for the same FR technology | Widely produced in China |

| THPC finishing Fabric | Refers to the finishing process | Equal performance to Proban |

For buyers sourcing from China: THPC finishing Fabric is the correct term, delivering Proban-equivalent performance.

5. Key Advantages of Proban / THPC Finishing Fabric

- Strong Flame Protection: The THPC–ammonia reaction creates a permanent polymer inside the fibers, providing reliable flame resistance.

- Excellent Washing Durability: These two types of fabrics can withstand up to 50 to 100 industrial washes and maintain their flame-retardant properties throughout their entire lifespan.

- Comfortable and Breathable: Made from cotton or cotton blends, THPC finishing Fabric retains natural softness and breathability for long-term wear.

- Compliant with International Standards: THPC Fabric can meet EN ISO 11612, EN ISO 11611, NFPA 2112, and ASTM F1506.

6. Applications of THPC / Proban-Type Fabric

- Oil & Gas protective clothing

- Welding garments

- Electrical utility PPE

- Industrial workwear

- Military and police uniforms

- Metalworking and foundry garments

8.FQA

Q1. Is THPC Fabric safe for daily wear?

Yes. After oxidation and washing, THPC finishing Fabric is clean, skin-safe, and compliant with international FR standards.

Q2. Is THPC Fabric durable?

Yes. Its cross-linked structure ensures excellent washing durability — far better than non-durable FR finishes.

Q3. Why do suppliers use the term “THPC finishing Fabric”?

Suppliers use ‘THPC Finishing Fabric’ to clearly convey the applied chemical technology and its recognition in industrial textiles.

Q4. Can THPC Fabric replace Proban Fabric?

Yes. Performance is equivalent, making THPC finishing Fabric a reliable alternative.

9. Summary for Buyers

- Proban Fabric and THPC finishing Fabric are technically the same flame-retardant technology

- Manufacturers and suppliers widely use the term THPC Fabric in China and Asia

- Both provide durable, comfortable, and reliable flame protection

- THPC finishing ensures strong washing durability and compliance with global standards

- Suitable for industrial workwear, welding, oil & gas, and electrical PPE

If you are sourcing high-performance FR cotton fabrics, choose THPC Fabric as a reliable Proban-equivalent solution. It combines exceptional durability, superior comfort, and cost-effectiveness, ensuring optimal performance and long-lasting protection for industrial workwear.

Contact us: info@safe-guarder.com,Shirley@safe-guarder.com