When choosing flame retardant (FR) workwear, buyers often face a difficult trade-off: Protection vs. Comfort. Traditional FR fabrics provide strong protection, but they often lack flexibility. These stiff materials trap heat and limit comfort, which frustrates workers in hot environments.

Industry professionals simply call this technology ‘CP fabric.’ It revolutionized FR cotton by offering a solution that feels almost identical to untreated cotton. This guide explores the science behind Pyrovatex and its unique eco-friendly properties. We also explain why industries prioritizing comfort prefer this solution.

1. What is Pyrovatex (CP) Fabric?

The term ‘CP’ refers to Pyrovatex CP New. Ciba originally developed this chemical finishing technology, and Huntsman now owns it. This specialized technology targets 100% cotton fibers to provide superior flame resistance.

Temporary coatings often wash away. In contrast, the CP process uses a patented additive to form a permanent cross-link with the cotton fiber. Upon contact with fire, the fabric instantly generates a carbon char layer. This barrier cuts off oxygen and stops the spread of flames, forcing the garment to self-extinguish rapidly.

2. Top 3 Benefits of Pyrovatex (CP) Flame Retardant Fabric

Why do many European and high-end markets prefer CP fabric over other finishes? The answer lies in three key areas:

A. Superior Softness (Hand Feel)

The biggest selling point of CP fabric is its texture. The finishing process minimizes the stiffness often associated with FR treatments. The result is a fabric that is soft to the touch and comfortable to wear for long shifts. For workers in hot environments or those who need high mobility, CP cotton is often the top choice.

B. Low Formaldehyde (Eco-Friendly)

In the past, the market criticized traditional FR treatments for releasing high levels of formaldehyde. However, modern CP technology (Pyrovatex CP New) has solved this.

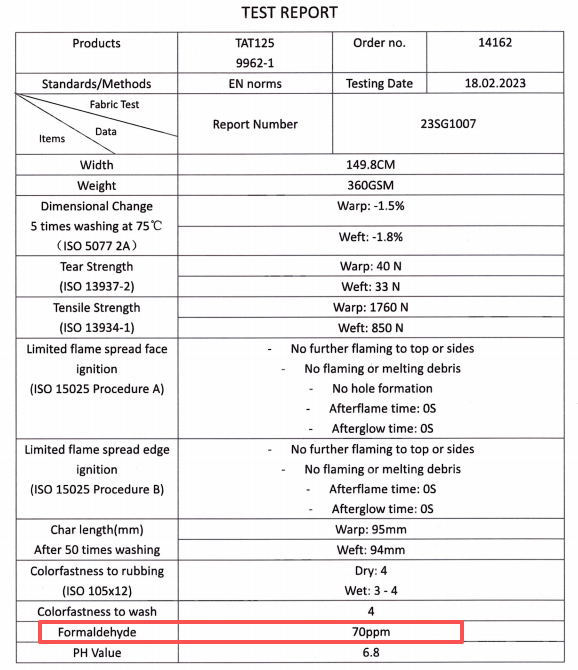

Caption: Actual test report: Our CP fabric contains only 70ppm formaldehyde, ensuring eco-friendly safety.

-

The free formaldehyde content in finished CP fabrics is strictly controlled to be less than 75ppm.

-

This meets strict international environmental standards, including the Oeko-Tex Standard 100 (Class II) (Link to page 22) . This makes CP fabric a “green” product that is safe for direct skin contact and poses no harm to the human body.

C. Vibrant Colors & Superior Lightfastness … More importantly, CP fabric exhibits exceptional lightfastness (resistance to UV fading).

- Global Application: This technical advantage makes the fabric perfect for regions with extreme UV exposure. It thrives in harsh environments like Australia’s mining belts, Chile’s high-altitude mines, and the scorching oilfields of the Middle East and Texas. In these environments, standard FR workwear often fades and looks “old” within weeks.

- Market Reality:Despite this technical fit, the fabric’s premium production cost influences global adoption. Currently, we see the highest demand in Northern Europe (Nordics) and the UK. These markets prioritize long-term durability and premium corporate image, justifying the investment despite the higher price point.

3. Durability: How Long Can Pyrovatex (CP) Fabric Last?

CP fabric combines exceptional comfort with robust protective performance.

-

Washing Standard: A high-quality CP fabric can maintain its flame-retardant index even after 50 industrial washes.

-

Safety Standards: It easily passes major international standards such as EN ISO 11611, EN ISO 11612, and ASTM D6413.

(Link Opportunity: “Looking for even higher durability for harsh industrial laundry? Check out our guide on [Proban/THPC Fabric] which can withstand 100+ washes.”)

4. Limitations of CP Fabric (Pros & Cons)

At SAFE GUARD, we adhere to a policy of full technical transparency. While Pyrovatex (CP) fabric delivers superior performance, there are inherent technical characteristics that buyers must consider.

1.Strength Considerations: The acidic conditions during the CP process inevitably weaken the cotton fiber slightly. Typically, there may be a 15-20% strength loss compared to the original fabric.

· Our Solution: First, we select high-strength cotton yarns to ensure durability. Second, we strictly control the pH value during production to minimize fiber damage.

2. Cost: Achieving low formaldehyde relies on patented chemicals and complex processing. As a result, CP fabric costs more than standard THPC fabrics. Typically, the price point is approximately 10% higher than comparable Proban fabrics.

5. Ideal Applications for Pyrovatex (CP) Fabric

Given its balance of comfort and safety, Pyrovatex (CP) fabric is best suited for:

-

Electrical & Utility Workers: Who need comfort for all-day wear.

-

Supervisors & Engineers: Who require professional-looking, fitted garments.

-

Hot & Humid Climates: Regions where breathable, lightweight fabric is a mandatory requirement.”

-

European Markets: Where strict environmental regulations (REACH, Oeko-Tex) are mandatory.

6. FAQ: Technical Inquiries Regarding Pyrovatex (CP) Fabric

Q1: Is “CP fabric” equivalent to Pyrovatex CP New technology?

A1: Yes. In the textile industry, ‘CP fabric’ is the standard term for cotton finished with Pyrovatex CP New. Ciba originally developed this flame-retardant technology, and Huntsman now owns it. References to “CP flame-retardant fabric” generally indicate materials treated with this specific chemical system.

Q2: Does Pyrovatex (CP)–treated fabric contain any measurable formaldehyde?

A2: Pyrovatex (CP) finishing may contain trace amounts of formaldehyde; however, modern Pyrovatex CP New formulations maintain free formaldehyde below 75 ppm. This level complies with Oeko-Tex Standard 100 (Class II) requirements and is considered safe for direct skin contact.

Q3: What is the expected wash durability of Pyrovatex (CP) flame-retardant performance?

A3: Pyrovatex (CP) is a durable finish, not a temporary coating. SAFE GUARD produces high-quality CP fabric that withstands at least 50 industrial washes. It maintains its flame-retardant properties to pass standards like EN ISO 11611 and EN ISO 11612.

Q4: Why does Pyrovatex (CP) fabric maintain a softer hand feel compared with other FR cotton fabrics?

A4: The Pyrovatex (CP) cross-linking mechanism is engineered to minimize fiber rigidity. Some FR treatments leave a rigid polymer layer on the surface. In contrast, CP finishing preserves the natural softness of cotton. This enhances comfort significantly in warm or humid environments.

Q5: What key factors determine the optimal choice between Pyrovatex (CP) and Proban?

A5: Both technologies provide effective flame protection, but their strengths differ:

-

Choose Pyrovatex (CP) if you need maximum comfort (softness) and strict low-formaldehyde compliance.

-

Choose Proban if you need maximum tear strength and extreme washing durability (100+ washes).

Conclusion

Does your project demand maximum worker comfort and strict environmental compliance? If so, Pyrovatex (CP) fabric is the ideal solution. It seamlessly combines the natural hand feel of cotton with the trusted protection of modern chemical engineering.

However, selecting the optimal FR fabric often requires balancing performance with cost efficiency. Our upcoming technical evaluation comprehensively compares Proban (THPC) versus Pyrovatex (CP) to help you identify the most strategic investment for your business.

For immediate assistance with your procurement strategy, we invite you to consult the SAFE GUARD engineering team directly. Please contact us via [info@safe-guarder.com] to request a [tailored CP fabric solution] and a detailed cost-efficiency assessment customized to your operational needs.